Predictive analytics in the manufacturing industry is a process that deals with data analytics and uses the collected information to predict future outcomes, applying statistical algorithms and data mining methods. The idea behind using predictive analytics for manufacturing industry is to increase process quality and respond to demands instantly. Using reliable techniques, you can manage and control customer demands by forecasting the future based on history and stored data. Companies in the industry now face a remarkable amount of data from different sources.You can view the data as an uphill battle for your company or use advanced algorithms to extract new opportunities for your industry’s future.- According to a survey, 63% of companies say the top benefit from data analytics is efficiency and productivity, and 57% prove that better decision-making processes are the top benefit of using this approach.

- 94% of business professionals emphasize that data analytics and related fields are essential for their digital transformation programs.

- 44% of companies believe they had better customer experiences using data analytics techniques.

In This Article, You Will Read:

Why is Digital Transformation Data Analytics Changing the Manufacturing Industry?

Considering all industry divisions, no other sector has experienced revolutionary changes like the manufacturing industry in recent years. You can call it the 4th industrial revolution, which differs from what we experienced decades ago. - Now, manufacturing processes are based on data-driven approaches, and the necessity of data analytics and predictive analytics in the manufacturing industry is influencing the industry and changing the whole process.

The digital transformation arrived with robust technologies, offering efficiency and high computing speed, both with one insight. You can’t deny the advantages of using high-speed computing processes in daily life, and this approach can be implemented in more complex conditions in the industry. We look at the digital transformation and industry revolution 4 as great opportunities that provide efficient product manufacturing and help design simple solutions for complicated tasks in the industry and manufacturing sector.- Nearly 90% of jobs require digital skills now or in the coming years.

- 70% of organizations say they have a digital transformation strategy or are spending on one.

Source: FinancesOnlineWhat is Predictive Analytics in Manufacturing Industry?

Predictive analytics in the manufacturing industry have been around for many years, and it is not a new normal. Decades ago, all manufacturers implemented predictive analysis to forecast needs, customer demands, and market changes. But, it was based on traditional techniques that don’t make sense in our booming world with high volumes of data coming from different sources.- Data computing and analytics are now more complex than decades ago.

- Growing volumes of manufacturing data can be challenging, causing concerns about how you will store and analyze them.

- The need for instant decision-making makes the situation even worse, and this time, traditional data collecting and computing will be abandoned in favor of more reliable techniques.

Predictive analytics in the manufacturing industry became popular due to its super-efficient solutions for storing mass business data and computing with trustworthy algorithms. Predictive analytics extract valuable information from the collected data and use it to forecast future market demands and business opportunities. - This can be a game-changer for manufacturing companies that desire to expand their marketing efforts and gain more market share, especially in international markets.

Use Cases of Predictive Analytics in Manufacturing Industry

Predictive analytics in the manufacturing industry provides highly efficient methods to cut unnecessary costs and adapt to market circumstances. You can implement the solutions in the following use cases, which offer enhanced manufacturing processes and supply chain management.- Predictive maintenance: The industry’s machinery and manufacturing equipment need to be checked and maintained regularly to ensure the quality of products and workflow. Dataconomy says machinery failures and downtimes could cost up to 22,000 dollars per minute for your manufacturing industry.

- Market demand forecasting: Demand forecasting and understanding customer needs are fundamental factors for big companies’ success. To thrive in competitive markets, you need to respond instantly to customer demands and market changes.

- Employee management: Predictive analytics can be implemented in the manufacturing industry to notice workforce requirements and needed skills. Data analytics in the industry provides an intelligent system for labor management to control the hiring process.

- Integration with ERP and MES software systems: You can use manufacturing data analytics alongside the Manufacturing Execution System to increase the process quality and forecast all the requirements.

The Benefits of Predictive Analytics in Manufacturing Industry

Artificial Intelligence allied with data analytics in manufacturing offers outstanding benefits for developing new solutions for the industry. The remarkable benefit of manufacturing data analytics is that it detects problems at the early stages, giving you significant time to resolve them and find solutions.This advantage is one of the industry’s long-desired requests, and manufacturers achieve a flexible workflow by using forecasting methods to spot obstacles and profitable opportunities. - What business opportunity is the most valuable for your company?

- When is the best time to take action and start new business frontlines?

- What are the market demands, and what is the market pull for a specific product?

You may accentuate your company’s ROI rate, which is crucial for every business in the industry. This is when the data analytics software and digital transformation come in and offer reliable methods to improve ROI rates and cut incurred costs.

Contact our experts

Don’t hesitate to contact us!

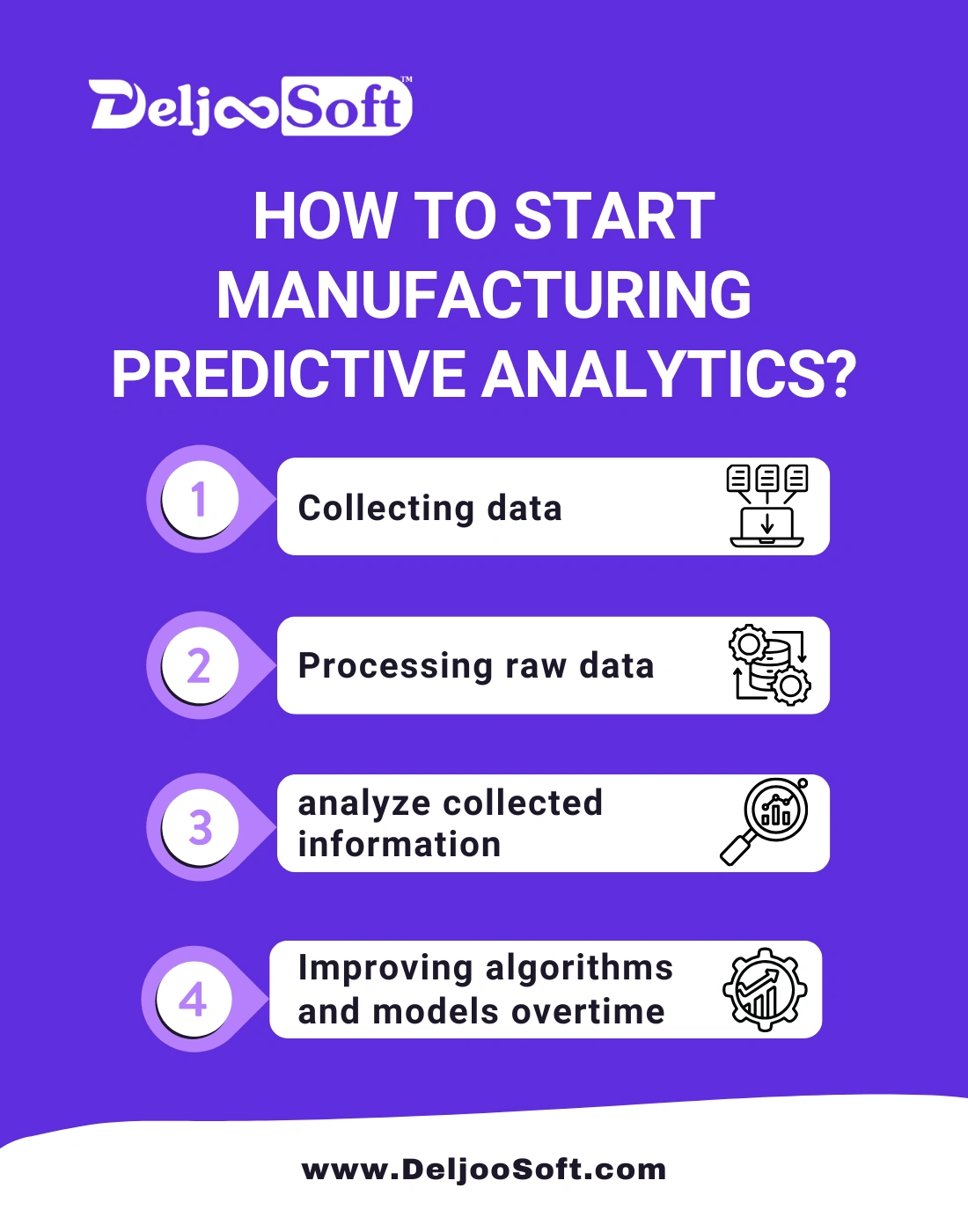

How to Start Manufacturing Predictive Analytics?

To implement predictive analytics in manufacturing industry solutions in your company, you have a few steps. The first step is to collect the required data from the defined resources, such as sensors, machines, and other parts of the production process. The data is stored and maintained using trustworthy techniques to prove its security and reliability. Within the storage process, we need to take care of some metrics to structure data so we can use and analyze it properly. Also, some types of information should be ignored because they don’t add value. Then, the information must be processed and visualized to extract helpful reports. Altogether, we can specify the process in the four steps as follows:

Altogether, we can specify the process in the four steps as follows:- Collecting data from approved sources

- Processing raw data to get rid of misleading information

- Using trusted models and high-speed platforms to analyze collected information

- Improving algorithms and models overtime to get the best results

Why Choose DeljooSoft?

Predictive analytics in the manufacturing industry are often performed over cloud platforms, and cloud computing has every tool you need to deploy high-speed algorithms. DeljooSoft provides cloud migration services that combine all data collecting and computing approaches in one environment.You can benefit from detailed reports that cloud manufacturing and digital transformation offer for an advanced manufacturing process. We deliver cloud computing solutions for industry-level companies based on the Azure platform. The Azure cloud platform is a unique digital transformation capability that enables companies to integrate all the features and software tools in one place.Our Portfolio

Predictive analytics in the manufacturing industry help your company determine critical points that may incur extra costs in the production process. If you implement your data properly, you can detect errors and issues just in time and even before they occur. Also, several opportunities exist to expand your business with digital transformation methodologies. We have plans for manufacturing companies and industrial companies to boost their ROI with cloud computing solutions.Conclusion

The way you use data analysis in manufacturing defines your success or failure. There is a notable amount of useless data in industrial companies that we don’t need, and we simply ignore it to get the best information. The predictive analysis focuses on this type of valuable data to forecast future market demand and customer needs. Also, you can detect the issues of machinery and equipment before they cause significant barriers to your business. If you want an advanced industry and competitive business, now is the right time to utilize data analytics in your company. Please feel free to contact our experts using the information below.Contact our experts

Don’t hesitate to contact us!

Our Cloud Development Services

Cloud development services have been designed to promote your company to the next level of growth. Using cloud technology, you can possess every tool in an on-demand and high-performance environment, and this is the distinctive feature of digital transformation for Industry Revolution 4. Predictive analytics in manufacturing industry is an integrated capability of digital transformation and cloud technology that extends your plans to make your company a modern organization.

Altogether, we can specify the process in the four steps as follows:

Altogether, we can specify the process in the four steps as follows: